Premier Cable Manufacturer in China

The advantages and disadvantages of mineral insulated cable

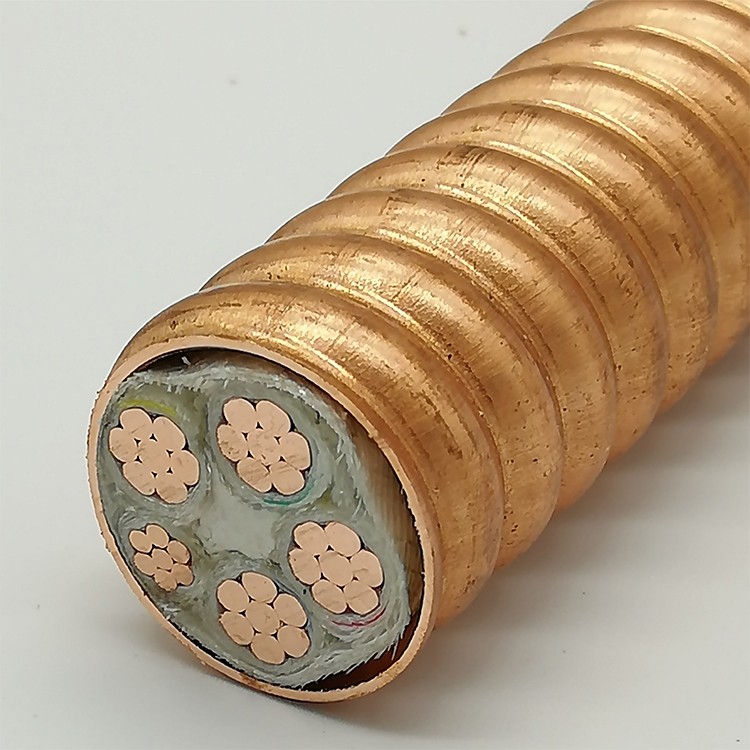

Mineral insulated cable is a new type of cable with seamless copper tube jacket, mineral crystal powder filled in the middle as insulation material, and a copper rod as conductor. Not only high temperature resistance, fire prevention, explosion proof, flame retardant, but also large load capacity, small diameter, high mechanical strength, long life, generally do not need independent grounding wire. Mineral cable models are divided into BTTQ light cable and BTTZ heavy cable two, its specifications are mainly single core, three core four core and so on. 1 core to 4 core mineral cable is mainly used for power, lighting, so, the following to understand the advantages and disadvantages of mineral insulated cable!

Advantages of mineral insulated cable:

1. Completely fireproof mineral cable itself does not burn at all. When burned by flame, it will not produce toxic smoke and gas

2. Strong overload protection ability. Line overload, as long as the heat does not reach the melting point temperature of copper, the cable will not be damaged;

3. Good anti-corrosion and explosion-proof performance. Due to the use of seamless copper tube as a sheath, mineral cable has waterproof, wet, oil resistance and some chemical damage performance, copper tube has considerable mechanical strength, so it has better explosion-proof performance;

4. Great flexibility in laying. Mineral cable can not only be laid with ordinary cable bridge, but also can be laid by special bracket, which is more flexible than ordinary cable laying, but also can save the investment of cable bridge and reduce the overall cost of the project.

Disadvantages of mineral insulated cable:

1. The jacket of mineral cable with high investment cost is composed of seamless copper tube, so the total copper content is much higher than that of ordinary cable;

2. The joint is prone to moisture. The insulation layer is composed of minerals. The connector part and the end part of the cable are easy to react with the moisture in the air, and the electricity generates hydrogen minerals.

3. Construction is difficult. The hardness of the mineral cable is higher than that of the general cable, and the bending and forming of the junction box and the bridge are difficult;

4. Heavy construction workload. Mineral cables with specifications over 35mm are all single-core cables. If there is a 95mm cable, ordinary cables only need 5 conductors of 495 150 on the same skin.

From the comparison of economy, construction speed and daily maintenance of mineral insulated cable, it is found that flexible mineral insulated cable has irreplaceable advantages in civil field. Rigid mineral insulated cable has good electrical and mechanical properties and is suitable for industrial applications.

If you are interested, pls feel free to contact us>>>

Copyright © 2020 Guangdong Cable Factory Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.