Premier Cable Manufacturer in China

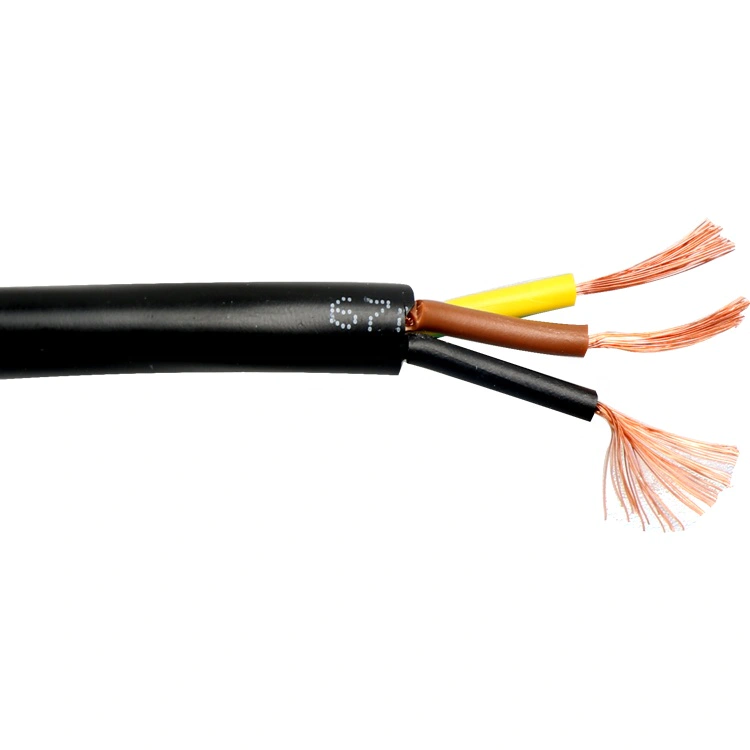

Characteristics and identification methods of low smoke halogen-free flame retardant wires

by:AAA

2020-03-01

What are the characteristics and identification methods of low smoke halogen-free flame retardant wires?

We don't know anything about low-smoke halogen-free flame retardant wires. Many people only know about wires, but they still know very little about wires for different purposes, therefore, if we want to know the low-smoke halogen-free flame retardant wire, we must first understand the characteristics and identification methods of the low-smoke halogen-free flame retardant wire?

The specific knowledge answer is as follows: what are the characteristics of low smoke halogen-free flame retardant wires?

Each kind of wire is used differently because it has characteristics that other wires do not have, therefore, before we buy low-smoke halogen-free flame retardant wires, let's first understand the characteristics of low-smoke halogen-free flame retardant wires. 1. Characteristics of low smoke halogen-free flame retardant wires--

The tensile strength is larger than that of ordinary PVC wires: the tensile strength of ordinary PVC wires is greater than 1.

05Kgf/mm2, while the tensile strength of low smoke halogen-free wire is greater than 1. 2kgf/mm2; 2. Characteristics of low smoke halogen-free flame retardant wires--Has good weather resistance (-30℃ ~ 105 ℃); Have good softness (Hardness 80-90); 3. Characteristics of low smoke halogen-free flame retardant wires--With non-mobility (

Because this product formula does not need to be added, there will be no Shape Shift); No toxic black smoke will be produced when burning (Will produce a small amount of white smoke);

High volume resistivity: PVC wires are generally 1012 ~ 1015 Ω/cm3, low smoke halogen-free wire greater than 1016 Ω/cm3; (7)

It has good high-voltage resistance: PVC wires are generally resistant to 10KV or more, while low-smoke halogen-free wires are as high as 15KV or more; (8)It has good elasticity and viscosity.

What is the identification method of low smoke halogen-free flame retardant wire?

1, low smoke halogen free flame retardant wire identification method of product name identification method. Wire--Low smoke halogen-free flame retardant polyethylene insulated wire and cable; Cable--

Low smoke halogen-free flame retardant polyethylene insulated low smoke halogen-free flame retardant polyethylene sheathed power cable.

Imitation products generally have a little different name, such as polyethylene insulated low smoke halogen-free sheathed flame retardant power cables and so on.

2, low smoke halogen free flame retardant wire identification method of skin burning method.

There should be no obvious depression in the insulation layer when ironing with an electric soldering iron. If there is a larger depression, it indicates that the material or process used in the insulation layer is defective.

Or barbecue with a lighter. Under normal circumstances, it should be difficult to ignite. After burning for a long time, the insulation layer of the cable is still relatively complete, without thick smoke and pungent smell, and the diameter increases at the same time.

If it is easy to ignite, it can be determined that the insulation layer of the cable does not use low smoke halogen-free materials (

It is likely to be polyethylene or crosslinked polyethylene material).

If there is a large smoke, it means that the insulating layer uses halogen-containing materials.

If the insulation surface falls off seriously after burning for a long time and the diameter does not increase significantly, it means that no suitable irradiation crosslinking process has been carried out.

3, low smoke halogen free flame retardant wire identification method of hot water immersion method.

Soak the wire core or cable in hot water at 90 ℃. Under normal circumstances, the insulation resistance will not drop rapidly and remain at 0. Above 1 MΩ/Km. For example, the insulation resistance drops rapidly or even lower than 0.

009 MΩ/Km, indicating that there is no appropriate irradiation crosslinking process. (

Polyethylene or cross-linked polyethylene insulation materials are not suitable for this method of identification, and can be identified by the method of the above second article).

4. Density comparison method for identification methods of low smoke halogen-free flame retardant wires.

The density of low smoke halogen-free material is higher than that of water, so a little insulation layer can be peeled off and put into water. If it floats above the water surface, it is definitely not low smoke halogen-free material.

The above is a brief introduction to the characteristics and identification methods of low-smoke halogen-free flame retardant wires. After we understand the characteristics of low-smoke halogen-free flame retardant wires, we even know about such wires, I hope the introduction of the above editor can help everyone.

Custom message