Premier Cable Manufacturer in China

Several reasons why European countries do not use aluminum alloy cables

by:AAA

2020-03-13

The aluminum alloy used as a conductor was a cable alternative conductor material that began to be extensively studied due to the high-speed rise in copper prices from the 60 s to 1970s s.

Aluminum Alloy used as conductor mainly includes AA1000 series, namely pure aluminum, AA6000 and AA8000 series conductors.

AA1000 series conductors are mainly used in high voltage overhead lines; AA6000Al-Mg-Si (-Aluminium-magnesium-silicon alloy)

Series conductors are mainly used in high-voltage overhead lines and aluminum bus bars;

These two types of conductors are hard conductors, and the connection of joints is mainly welding. AA8000Al-Mg-Cu-Fe (Aluminum-magnesium copper iron alloy)

The series is a soft aluminum alloy that is really used in distribution lines.

In North America AA8000Al-Mg-Cu-Fe (Aluminum-magnesium copper iron alloy)

The series is only used in the field of low-voltage distribution networks, but not in Europe. European countries basically adopt solutions of copper core cables and pure aluminum cables.

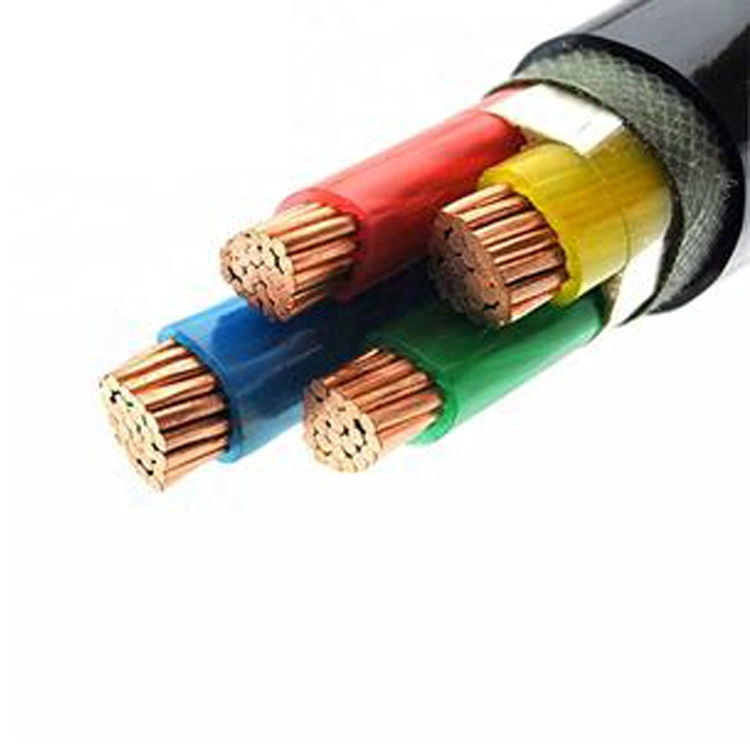

European countries have not adopted the technical route of aluminum alloy cables, mainly due to the following aspects: 1. Comparing the electrical properties of copper core cable and aluminum alloy cable, copper material and aluminum material are obviously different in electrical and mechanical properties.

Aluminum Alloy wires are similar to pure aluminum in conductivity and resistivity, so only 1.

6 times the method can achieve the electrical performance of copper cable.

That is to say, the most basic performance of aluminum alloy cable is not substantially better than pure aluminum in terms of conductivity and resistivity. This is the first reason why European countries did not choose aluminum alloy cables.

2. Comparing Copper core cable and aluminum alloy cable from the perspective of energy consumption, G of University of Bath, UK. P. Hammond and C. I. Jones [5]

The energy consumption contained in the production and use of different raw materials used in the power grid is deeply compared and studied, as shown in Table 2.

It can be seen that the energy consumption of metal aluminum in the production and use process is about 3 times that of copper.

Aluminum and Aluminum alloy cables consume more energy in production and use than copper cables.

3. The carbon displacement and environmental impact of aluminum alloy cables are significantly higher than that of copper cables according to G of University of Bath in England. P. Hammond and C. I. Jones [5]

A comparative study of carbon dioxide emissions from different raw materials used in the power grid during production and use is shown in Table 3.

It can be seen that the carbon dioxide emission of metallic aluminum is twice that of copper.

In addition, WimBOONE of the Netherlands and ArnavKACKER of Germany pointed out in their article 'widely comparing copper core cable wires or aluminum core cable wires from the perspective of life cycle' that the impact of aluminum alloy cables on the environment (Acidification potential)It is also higher than copper cable.

4. The cost of the whole life cycle the price of aluminum is far lower than that of copper, thus making aluminum alloy cables have a price advantage and bringing profit margins to Cable Enterprises, however, through the comparative study of the whole life cycle cost of cables in European countries, it is concluded that aluminum alloy cables have no obvious advantages over copper cables.

Usually power cables can be used for 35 to more than 50 years.

However, the cable investment decision is mainly based on the investment cost, which ignores the cost savings that may be included in the cable service life. Cable Total cost of ownership (Hereinafter referred to as 'life cycle cost ')

Not only the initial cost of the cable should be considered, but also the operation and maintenance costs of the cable life should be considered.

Therefore, the overall life cycle cost should include the capital expenditure and operating cost during the service life of the cable. Only in this way can it be possible to use such as copper, choose more economical conductive materials among aluminum and other materials.

WimBOONE in the Netherlands and ArnavKACKER in Germany, through the life cycle cost analysis (LCCA)The following conclusions are drawn: 1)

The cost difference between copper cables and aluminum cables has been greatly reduced during its operation.

In all cases, the cost difference during the operation period is about 3%, and in some cases, copper cables even become the lowest life cycle cost. 2)

If only one-time investment and procurement costs are considered, aluminum alloy cables and aluminum materials undoubtedly have great advantages, but from the analysis of the whole life cycle cost of copper and aluminum cables, there is almost no difference between the cost of copper and aluminum, compared with aluminum alloy cable, copper cable is better than aluminum alloy cable in terms of life cycle cost.

Conclusion: European countries do not adopt the technical route of aluminum alloy cables, this paper mainly studies and demonstrates the electrical performance, energy consumption, carbon dioxide emission, environmental impact and life cycle cost of copper core cables and aluminum alloy cables, therefore, it is concluded that aluminum alloy cables are not suitable for European countries.

Custom message