Premier Cable Manufacturer in China

Method for preventing oxidation of General rubber cable conductors

by:AAA

2020-03-04

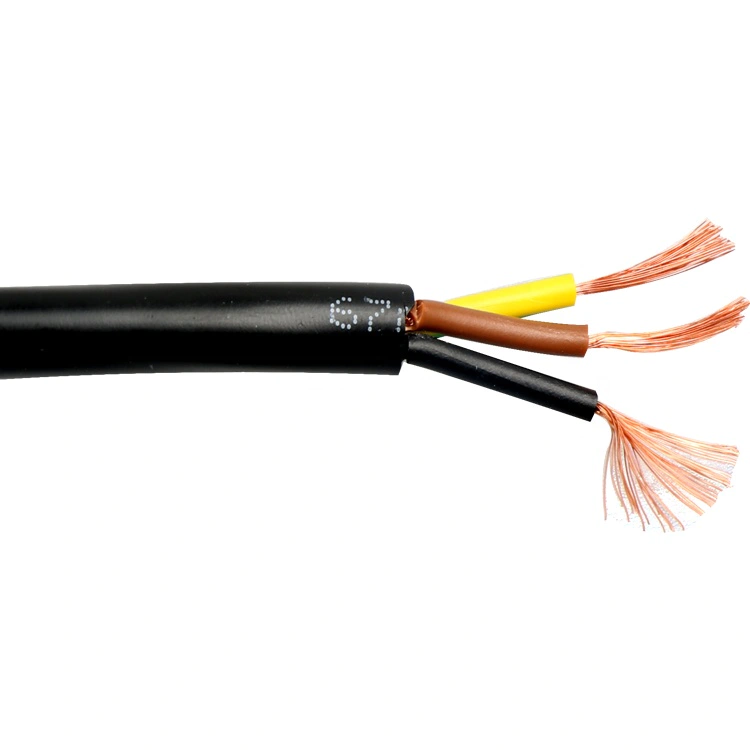

General rubber sheathed cable uses five kinds of copper conductors as conductive wire cores. In its production process, copper conductors are often found to be oxidized and discolored, which seriously affects the quality of products, it has become a long-standing technical problem for many cable manufacturers in China.

Copper is a transition metal and is easily oxidized into black CuO by oxygen in the air under acidic conditions.

When there is a water film or water bead on the surface of the copper conductor, because the atmosphere contains a lot of dust, such as smoke, coal, automobile exhaust, chloride and other acid, alkali, salt particle dust, etc, these harmful substances are dissolved in the water film or water droplets, which can form an electrolyte, thus aggravating the oxidation discoloration of the copper conductor.

The lighter affects the appearance quality and product quality of the product, while the heavier affects the use of copper conductors, resulting in waste of production costs.

Therefore, copper conductors must be properly kept, pay attention to anti-oxidation discoloration.

In principle, the metal copper for cables mainly includes physical methods to block the contact between copper and humid air, cathodic protection oxidation-reduction method to prevent the oxidation of copper conductors, and chemical methods to generate a passivation film on the surface of copper conductors to prevent oxidation, or spray special liquid on the surface of the conductor to protect it.

Taking the production of Universal rubber sheathed cables as an example, the main method of anti-oxidation control in each process.

1. Copper poles should be transported, tested and stored before entering the factory. Most cable enterprises in our country use copper as outsourcing, so they should choose high-quality metal copper poles to standardize the transportation and delivery procedures and systems of suppliers, the copper rod entering the factory shall be inspected in accordance with GB/T 3048. 2 or cable Enterprise Enterprise standard execution.

The storage of the copper rod can be covered with plastic cloth or plastic film, that is, the simplest physical barrier method to prevent the copper rod from contacting with humid air.

When the workshop uses the copper rod, it is necessary to check the copper rod roll one by one for the black phenomenon, and control it from the production source.

2. Control of copper rod drawing process 0.

4mm the drawing of monofilament generally adopts copper lath and copper lath of continuous annealing, which needs to go through processes such as setting out, drawing and annealing, cooling, drying, taking up and so on.

First of all, the appropriate mold should be selected, and must not be too small, otherwise it will force the lattice variation of metal copper and aggravate the sharp rise of metal temperature.

Secondly, check the pH value of the emulsion before starting up to ensure that it is an alkaline solution. At the same time, antioxidants should be added to the wire drawing oil to form a passivation film on the surface of the copper conductor to prevent oxidation;

When setting out, keep the tension of setting out stable and uniform, and do not vibrate excessively;

During the wire drawing process, the operator should ensure the appropriate water level height, ensure the uniform annealing degree, and avoid insufficient annealing or excessive annealing;

When winding, there should be no residual liquid on the surface of the copper conductor, and a piece of dry felt can be placed in front of the winding (Replace frequently)To ensure the drying of monofilament.

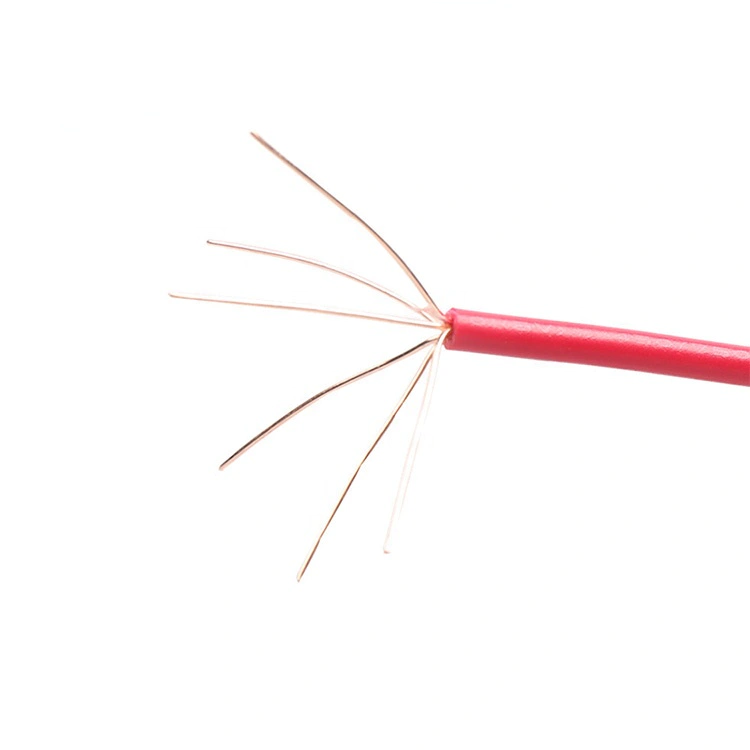

Finally, after drawing the plate, it is sealed with a transparent plastic film and stored in a dry environment to be circulated, otherwise it will be prone to oxidation with humid air due to the high surface temperature of the conductor. 3, copper wire stranded (Bunching)

In the extrusion process of insulating rubber and sheath rubber, taking copper wire stranding as an example, the conductor changes the structure of the metal copper lattice through each die during the stranding process, and under the action of strong external force, the temperature of the copper conductor after passing the mold is greatly improved compared with that before passing the mold, so the outer layer of the copper conductor is easy to oxidize.

Therefore, the infusion hose can be used to transfer the antioxidant (0. 3% benzotriazole in alcohol)

Dropping into the copper wire, the dropping standard is based on the surface of the copper wire, to avoid the phenomenon of too little local oxidation or too much waste, after all the anti-oxidation work is ready, then start the machine.

Take-up should ensure that the take-up tray is dry. After the take-up tray is filled, it should be sealed with transparent plastic film.

Before the conductor is extruded and insulated, it should be wrapped vertically or wrapped around the polyester tape, and the substance in the rubber insulation material should be placed to corrode the conductor.

Insulation rubber and sheath rubber in the extrusion process, should avoid the thread head water, and the occurrence of the thread head oxidation blackening phenomenon.

We found in our daily production observation that, by selecting high-quality copper rods, effectively controlling the wire drawing process, emulsion concentration and temperature, annealing process, passivation treatment on the surface of stranded conductor or stranded copper wire, and preventing the thread head from entering water, etc. , in addition, workshop operators should establish quality awareness, strengthen business training, clearly recognize the adverse consequences of copper wire oxidation, and strictly control the quality, so as to effectively control the quality of cable copper conductors and prevent their oxidation, it greatly improves work efficiency and reduces rework frequency, thus achieving the beneficial effects of reducing cost and improving internal product quality.

Custom message