Premier Cable Manufacturer in China

Machine vision is applied to the cable surface testing

by:AAA

2020-04-11

(

Industry news]

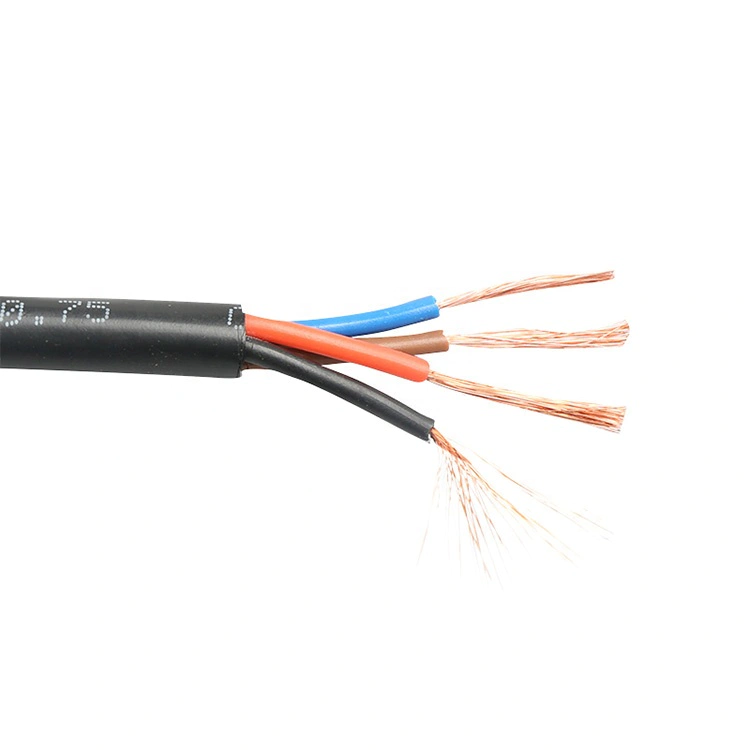

Machine vision is applied to the cable surface testing JDS P dagger see smart parsing technology: the power cable is mainly used for urban underground power grid, power stations, which leads to the line, industrial and mining enterprises of the internal power supply and power lines and other occasions, river and sea water control power cable is a kind of power cable, it is mainly used for transfer of control, measuring signal, etc.

Control the appearance of the power cable quality is very important, good product often pay great attention to appearance quality.

Control the appearance of the power cable check mainly includes which aspects?

Check the degree of roundness, round aluminum rod: requirements, whether to have ruffled, wrong circle, defects such as cracks, inclusions, kink and severe mechanical damage scabbing, hemp pit corrosion, peeling, flash, spots, etc.

, round copper wire, check whether the surface is bright and clean, and presence of triangle, crack, burr, folding and inclusions and serious scabbing, hemp pit, mechanical damage of corrosion spots, and so on and so forth.

Is worth questioning and the oxidation of copper wire, the copper wire and cable, as a general rule, be in tianjin golden, this is the normal color, pink for mild oxidation, surface for severe oxidation when dark red, blue, who shall be awarded to severe oxidation of waste treatment.

Aluminium wire line condition is more, in the process of manufacturing for overhead transmission line should be kept under strict control.

, aluminum surface: a line conductor should be twisted tightly neat, there can be no loose, kink of single, single out or bump and single fracture phenomenon, etc.

. In addition, the single joint welds should be rounded and welding has been asked to do the anti-corrosion treatment, increase the joint parts must not be more than twice the diameter tolerance in general, two single joint welds span length also want to accord with a standard, the same single wire welding place should not be less than two meters, the same layer of the same two welding wires is the layer of the spacing of not less than m, the outer layer is not less than m, copper core of single copper wire, welding is not permitted.

, the appearance of the cable structure size: the appearance and structure size of the cable inspection generally is carried out by or at the same time, the quality of products on the one hand, to see if the performance is good, but the quality of its appearance, structure size also account for certain proportion, the appearance and structure size of the product has an impact on the performance of the cable.

Cable the appearance of the product quality is very important, because appearance often can give customers the first impression, so, for the appearance of the product quality, production workers, and inspection personnel can not be ignored, should be strictly controlled, to ensure the appearance quality of cable products.

More information please click: cable appearance test HTTP / / WWW.

jiandaoshi。

com/Products/xlbmqxsjjc。

html

Custom message