Premier Cable Manufacturer in China

Everything You Need to Know About Solar Cables

Solar technology will be one of the green energy technologies of the future, and solar energy or photovoltaic (PV) is becoming more and more widely used in China. In addition to the rapid development of government-backed PV power plants, private investors are actively building plants and planning to put into production solar modules that will be sold worldwide.

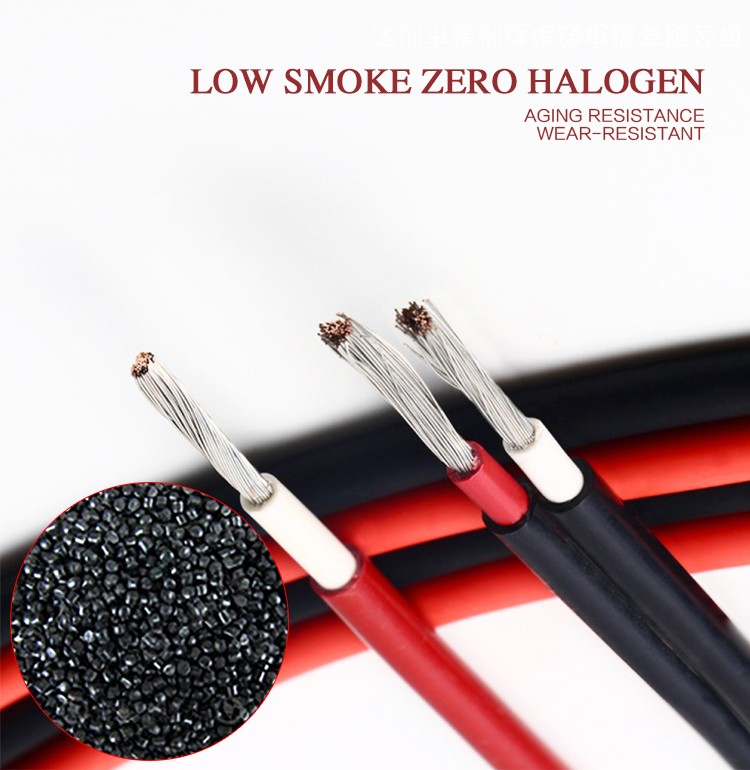

Solar cables, or PV-specific cables, have a conductor section of copper conductors or tinned copper conductors, an insulation layer of irradiated cross-linked polyolefin insulation, and a sheath of irradiated cross-linked polyolefin insulation. Photovoltaic power station in a large number of DC cables need to be laid outdoors, harsh environmental conditions, the cable material should be based on resistance to ultraviolet light, ozone, severe temperature changes and chemical erosion, moisture, sunlight, cold, heat, UV resistance, some special environments also need to prevent acid and alkali chemicals.

Common material cable in this environment for a long time, will lead to the cable sheath fragile, and even decomposition of the cable insulation layer. These conditions will directly damage the cable system, but also increase the risk of cable short-circuit, in the medium and long term, the possibility of fire or personal injury is also higher, greatly affecting the life of the system.

The advantages of solar cables compared to ordinary cables are:

Solar cables are often exposed to sunlight, and solar systems are often used in poor environmental conditions, such as low temperatures and ultraviolet radiation. In good weather at home or abroad, the maximum temperature at the site of the solar system will be up to 100°C.

Ordinary cables can generally be adopted from a variety of materials such as polyvinyl chloride (PVC), rubber, elastomer (TPE) and cross-linked polyethylene (XLPE) and other high-quality interwoven link materials, but unfortunately the maximum rated temperature of ordinary cable work is 90, and even the rated temperature of 70 ℃ polyvinyl chloride insulated cable is often used outdoors, but can not meet the high temperature, UV protection, cold requirements.

Solar cable, in placement and application, the cable can be wired on the sharp edge of the roof layout, while the cable must withstand pressure, bending, tension, interwoven tensile load and resistance to strong blows superior to ordinary cable. If you use ordinary cable, the sheath anti-UV performance is poor, resulting in the aging of the cable sheath, which affects the service life of the cable, can lead to cable short circuit, fire and staff danger injury and other problems. Solar cable insulation sheath after irradiation, with high temperature resistance, UV radiation, oil resistance, cold resistance and other properties, service life of 25 years or more.

If you want to know more, please feel free to contact us >>

Copyright © 2020 Guangdong Cable Factory Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.