Premier Cable Manufacturer in China

Characteristics of high performance phase separation metal interlayer power cable

by:AAA

2020-03-12

Long-term operation practice shows that even if the sheath is intact, there will still be certain moisture or water vapor seeping into the cable core of the cable.

Therefore, the effect of improving the three-core water-blocking cable to three single-core water-blocking cable structure is better.

That is to say, it is firstly made according to the structure of single-core medium-voltage water-blocking cable, and then three single-core cables are twisted into cables instead of three-core cables.

The improved water-blocking cable has simple structure, good water-blocking effect, saving water-blocking materials and costs, and is conducive to the improvement of heat dissipation and current carrying capacity of the cable. At the same time, the manufacturing process is relatively simple, and it is easy to lay and connect during construction.

This product can prevent moisture from entering the inside of the cable and protect the insulation core from drying, thus prolonging the service life of the cable.

The phase-separated metal sheath high resistance water power cable is a brand-new structure. The production and manufacturing process of this product is simple and the product performance is excellent.

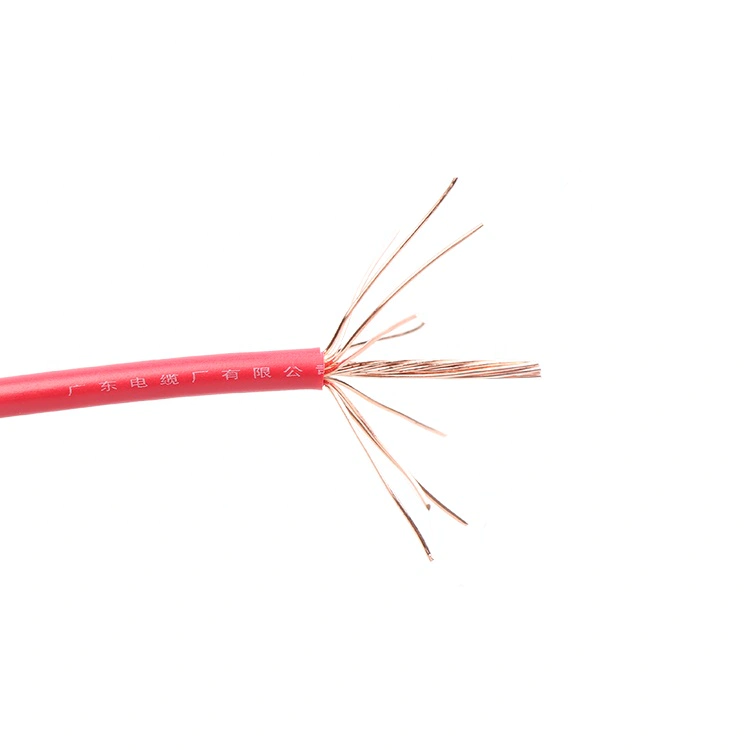

Main technical indicators of high-performance split-phase metal barrier power cable: ① technical indicators of power wire core: the conductor should be 1st or 2nd kinds of metal-plated or non-metal-plated annealed copper conductors or aluminum and aluminum alloy conductors in accordance with GB/t3956, or 5th kinds of bare copper or plated metal layer annealed copper conductors. Insulation, metal shielding (If any), Cable, inner guard (If any), Armored (If any)

External protection meets the provisions of relevant standards of GB/T12706.

(2) technical index of phase-separating metal sheath: after the phase-separating metal sheath is completed, the cable shall be inflated, and the test shall meet the following requirements: the cable shall be filled with 50-

100kPa dry air or nitrogen, within 3h after the full-length air pressure of the cable is balanced, the air pressure in the cable should not be reduced.

3 comprehensive waterproof technical indicators of the cable: The finished cable is soaked in water for 72 hours, the surface structure of the insulation is removed, and the insulation surface should be dry by eye observation.

Custom message