Premier Cable Manufacturer in China

cable manufacturing process

by:AAA

2021-03-04

Folding process

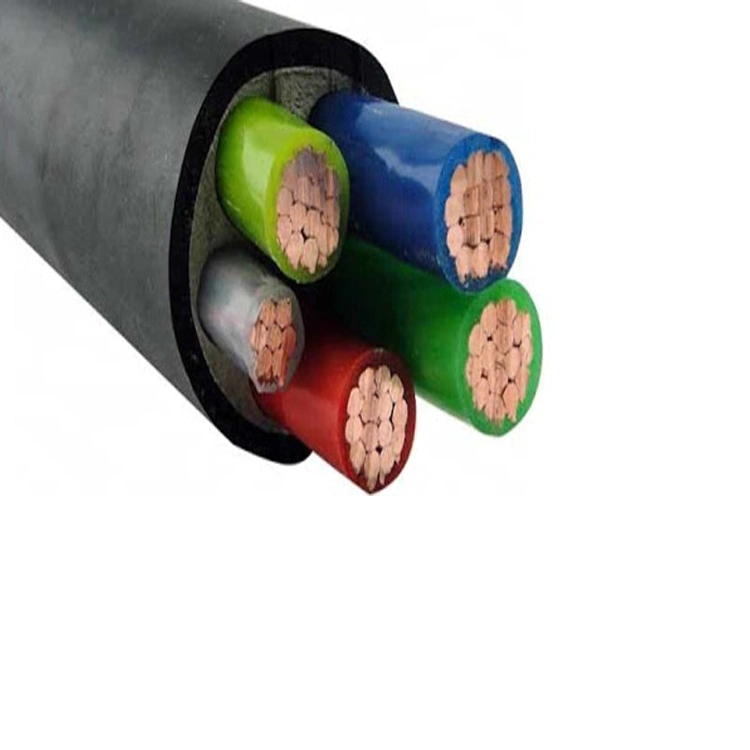

The manufacturing of wires and cables is completely different from the production of most electromechanical products. Mechanical and electrical products usually adopt the assembly of other parts into parts, and the assembly of multiple parts into a single product, and the products are measured by the number of units or pieces. Wire and cable are based on length as the basic unit of measurement. All wires and cables start from the processing of conductors, adding insulation, shielding, cabling, and sheathing layer by layer to the periphery of the conductor to make wire and cable products. The more complex the product structure, the more layers of overlap.

Folding process characteristics

1. The large-length continuous superimposed combined production method has a global and controllable impact on the production of wires and cables, which involves and affects:

(1) Production process and equipment layout

Various equipment in the production workshop must be reasonably discharged according to the technological process required by the product, so that the semi-finished products in each stage can be circulated in sequence. The equipment configuration should consider the different production efficiency and balance the production capacity. Some equipment may have to be equipped with two or more units in order to balance the production capacity of the production line. Therefore, the reasonable combination of equipment and the layout of the production site must be balanced and comprehensively considered according to the product and production volume.

(2) Production organization management

Production organization management must be scientific, reasonable, thorough, accurate, strict and meticulous. Operators must meticulously implement process requirements. Any problem in any link will affect the smoothness of the process and affect the quality and delivery of products. Especially for multi-core cables, if the length of a certain pair or basic unit is short, or there is a quality problem, the entire cable will be insufficient in length, resulting in scrap. Conversely, if the length of a certain unit is too long, it must be sawn to cause waste.

(3) Quality management

The production method of continuous superposition and combination of large length will cause any problem in any link of the production process to occur instantaneously, which will affect the quality of the entire cable. The more quality defects occur in the inner layer, and the production is not terminated in time, the greater the loss will be. Because the production of wires and cables is different from assembled products, they can be disassembled, reassembled and replaced; quality problems in any part of the wire and cable or the process are almost irreparable and make up for this cable. The post-event treatment is very negative, either cutting short or downgrading, or scrapping the entire cable. It cannot be disassembled and reinstalled.

The quality management of wires and cables must run through the entire production process. The quality management inspection department shall conduct roving inspections of the entire production process, self-inspection of operators, and mutual inspection of upper and lower procedures. This is an important guarantee and means to ensure product quality and improve the economic efficiency of the enterprise.

2. There are many types of production processes and large material flow

Wire and cable manufacturing involves a wide range of processes, from smelting and pressure processing of non-ferrous metals, to chemical technologies such as plastics, rubber, and paint; textile technologies such as wrapping and weaving of fiber materials, to wrapping and metal strips of metal materials Longitudinal package, welding metal forming processing technology and so on.

Various materials used in wire and cable manufacturing not only have many types, varieties, and specifications, but also a large number. Therefore, the amount of various materials, spare amount, batch period and batch must be approved. At the same time, the decomposition, recycling, reuse, and waste disposal of waste products are an important part of management, and we should do a good job in material quota management and pay attention to conservation.

In the production of wires and cables, from the entry and exit of raw materials and various auxiliary materials, the flow of semi-finished products from each process to the storage and delivery of products, the material flow is large, and reasonable layout and dynamic management must be made.

3. Many dedicated equipment

Wire and cable manufacturing uses special production equipment with the characteristics of the industry to adapt to the structure and performance requirements of cable products, and to meet the requirements of large-length continuous and as high-speed production as possible, thus forming a special equipment series for cable manufacturing. Such as extruder series, wire drawing machine series, stranding machine series, wrapping machine series, etc.

The manufacturing process of wire and cable is closely related to the development of special equipment and promotes each other. New process requirements promote the production and development of new special equipment; in turn, the development of new special equipment has promoted the promotion and application of new processes. Such as wire drawing, annealing, extrusion tandem lines; physical foaming production lines and other special equipment, promote the development and improvement of the wire and cable manufacturing process, and improve the product quality and production efficiency of the cable.

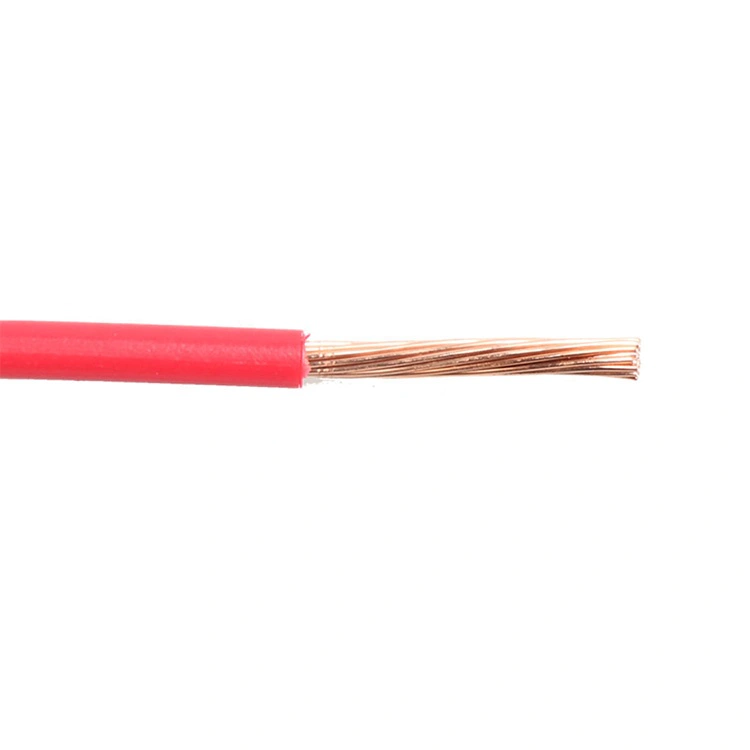

Second, the main process of wire and cable Wire and cable are made through three processes: drawing, stranding, and coating. The more complex the model and specification, the higher the repeatability.

1. Drawing

In metal pressure processing, the metal is forced to pass through the mold (press wheel) under the action of external force, the metal cross-sectional area is compressed, and the required cross-sectional area shape and size are obtained. The technical processing method is called metal drawing.

The drawing process is divided into: monofilament drawing and twisting drawing.

2. Stranding

In order to improve the flexibility and integrity of the wire and cable, two or more single wires are intertwined in a prescribed direction, which is called twisting.

The stranding process is divided into: conductor stranding, cabling, weaving, steel wire armoring and winding.

3. Coating

According to the different performance requirements of the wire and cable, special equipment is used to coat different materials on the outside of the conductor. Coating process points:

A. Extrusion: rubber, plastic, lead, aluminum and other materials.

B. Vertical package: rubber, corrugated aluminum tape material.

C. Winding: ribbon-shaped paper tape, mica tape, alkali-free glass fiber tape, non-woven fabric, plastic tape, etc., linear cotton yarn, silk and other fiber materials.

D. Dip coating: insulating paint, asphalt, etc.

Custom message