Premier Cable Manufacturer in China

Aramid (Kevlar) What is the difference between woven sheath and glass fiber woven sheath?

by:AAA

2020-03-19

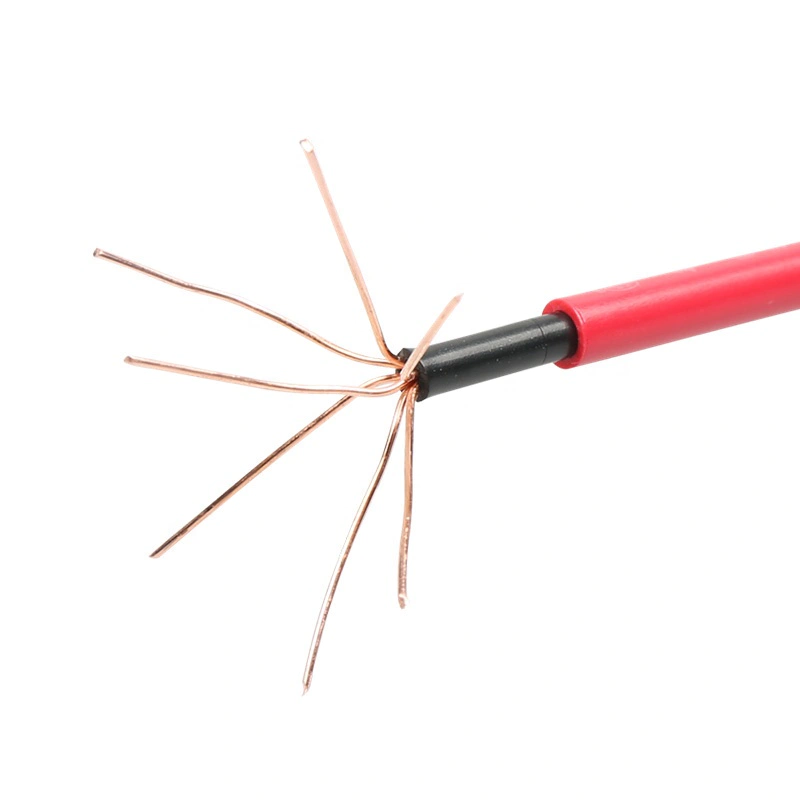

The function of fiber braid is to enhance the strength of conductor insulation layer and cable structure.

Under normal circumstances, the woven layer needs to be painted on the surface to improve wear resistance and prevent moisture immersion.

The painted layer is usually colored to facilitate circuit identification or improve the appearance of wires and cables.

Glass fiber and aramid are the most commonly used weaving materials.

Glass fiber has good thermal stability, softening temperature 700 ℃, melting temperature 1400 ℃. The decomposition temperature of aramid fiber is about 600 ℃. The average thickness of glass fiber woven layer is 0. 002-0. 035 inch (0. 05-0. 89mm).

The average thickness of aramid woven layer is slightly smaller, which is 0. 018-0. 040 inches (0. 457-1. 02mm).

Glass fiber is easy to color, and its appearance is bright and bright, and its natural color is natural white.

However, it is difficult to make aramid fiber into bright white. There are only other bright colors, but the appearance is light and plain.

The most prominent feature of aramid fiber is its wear resistance and shear resistance, and its strength is several times larger than that of glass fiber, so it has become the preferred material for the outer sheath of wires and cables.

Custom message