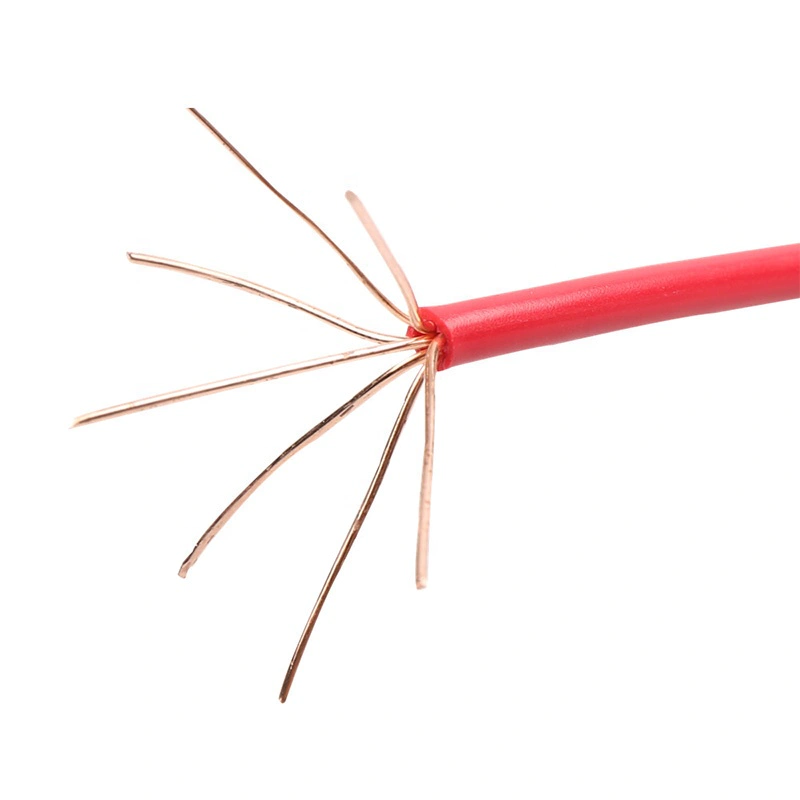

Premier Cable Manufacturer in China

Application - insulated cables in communication engineering Wire and cable

by:AAA

2020-08-14

Insulated cables in the application of communication engineering to insulated cables in communications engineering the application of the DHV use in power distribution system overhead insulated cables instead of overhead bare wire is an important safety power supply and guarantee measures of communication open.

As overhead insulated cable insulation material with polyvinyl chloride (

PVC)

, polyethylene (

PE)

And in recent years developed crosslinked polyethylene (

XLPE)

。

At present most countries abroad described. properties of overhead lines have been used as a substitute for the traditional PVC.

Described. properties insulation material heat resistance of the cable has the advantage of higher than PVC, it can be running under ℃ for long time, once the short circuit when the highest temperature resistant to ℃;

Described. properties of high insulation resistance, dielectric loss is small, and their basic not change with temperature;

Described. properties insulating layer with good wear resistance and resistance to environmental stress cracking;

XlP event of burning is from carbon dioxide and water, and that, when burned, PVC cable pests is hydrogen chloride gas, there is also a advantage is described. properties density is smaller than PVC %, can significantly reduce the weight of the overhead lines.

Most described. properties overhead cables with electron irradiation processing to speed up the crosslinked PE, the black crosslinking polyethylene material is in low density polyethylene resin add a certain amount of antioxidants, crosslinking agent, carbon black and other processed by mixing, extruding and into.

The addition of crosslinking agent can make PE to achieve the same degree of crosslinking reduce under the condition of electron beam irradiation dose, to improve the production speed and save energy is good, but the crosslinking agent also cannot too much crosslinking excessive, otherwise become hard and brittle materials.

Communication covering materials for cable insulation materials, communications wire, covering materials for cable and cable filling material in different PE grade manufactured by the method of blending modification, melt extrusion.

Communication cable production line USES high-speed production line, extrusion ultra-thin insulating layer, the traction speed up to m/min, so polyethylene insulation materials have special requirements for this purpose: should have excellent low temperature flexural resistance, abrasion resistance, environmental stress cracking resistance, processability, suitable for high speed extrusion, thin layer and can be widely used in aerial or buried telephone cable.

Communication optical cable diameter generally small, easy to bend, need high density polyethylene sheath material, in order to improve the wear resistance and resistance to environmental stress cracking on the surface of the fiber optic cable.

In order to make the cable padding is not too hard, most of the modification of low density polyethylene as a filling material in fiber optic cables.

Custom message