Premier Cable Manufacturer in China

AAA cable types and applications

by:AAA

2021-03-04

Fold type

Flame-retardant rubber sheathed cable

1. Purpose

This product is a series of mine-used rubber sheathed flexible cables. It is suitable for power connection of shearers and similar equipment with rated voltage Uo/U of 1.9/3.3KV and below. Mostly used in coal mines.

2. Conditions of Use

The long-term allowable working temperature of the core is 65℃, and the minimum bending radius of the wire is 6 times the diameter of the cable. The yellow sheathed cable shall not be exposed to sunlight for a long time.

Nuclear grade cable

Scope of application

・This product is suitable for the control and signal connection cables used in the control system network of nuclear power plants with a rated voltage Uo/U of 0.6/1kV.

・The allowable long-term working temperature of the cable conductor is 90℃, the maximum temperature of the cable conductor during short-circuit does not exceed 250℃, and the duration does not exceed 5 seconds.

・The ambient temperature when laying the cable should not be lower than 0℃.

The allowable bending radius during cable laying is:

-Non-armored cables should not be less than 6 times the diameter of the cable

-Cables with armored or copper tape shielding results should not be less than 12 times the cable diameter

-Flexible cables with shielding structure should not be less than 6 times the diameter of the cable.

・When the conductor's long-term allowable working temperature is not greater than 90°C, the cable's appraisal life span is not less than 40 years.

・The finished cable should meet the requirements of Class A bundled combustion test specified in the GB/T18380.3 standard.

・Smoke density of finished cable: light transmittance is not less than 70%.

Radiation resistance: 25×104Gy

・Halogen-free: When non-metallic materials are burned, the acidity (expressed in PH value) of the escaped gas should be greater than 4.3; the conductivity should not be greater than 10μS/mm.

Bare wires and bare conductor products

The main features of this category of products are: pure conductive metal, no insulation and sheath, such as steel core aluminum stranded wire, copper-aluminum busbar, electric locomotive wire, etc.; the processing technology is mainly pressure processing, such as smelting, rolling, drawing The products are mainly used in suburbs, rural areas, user main lines, switch cabinets, etc.

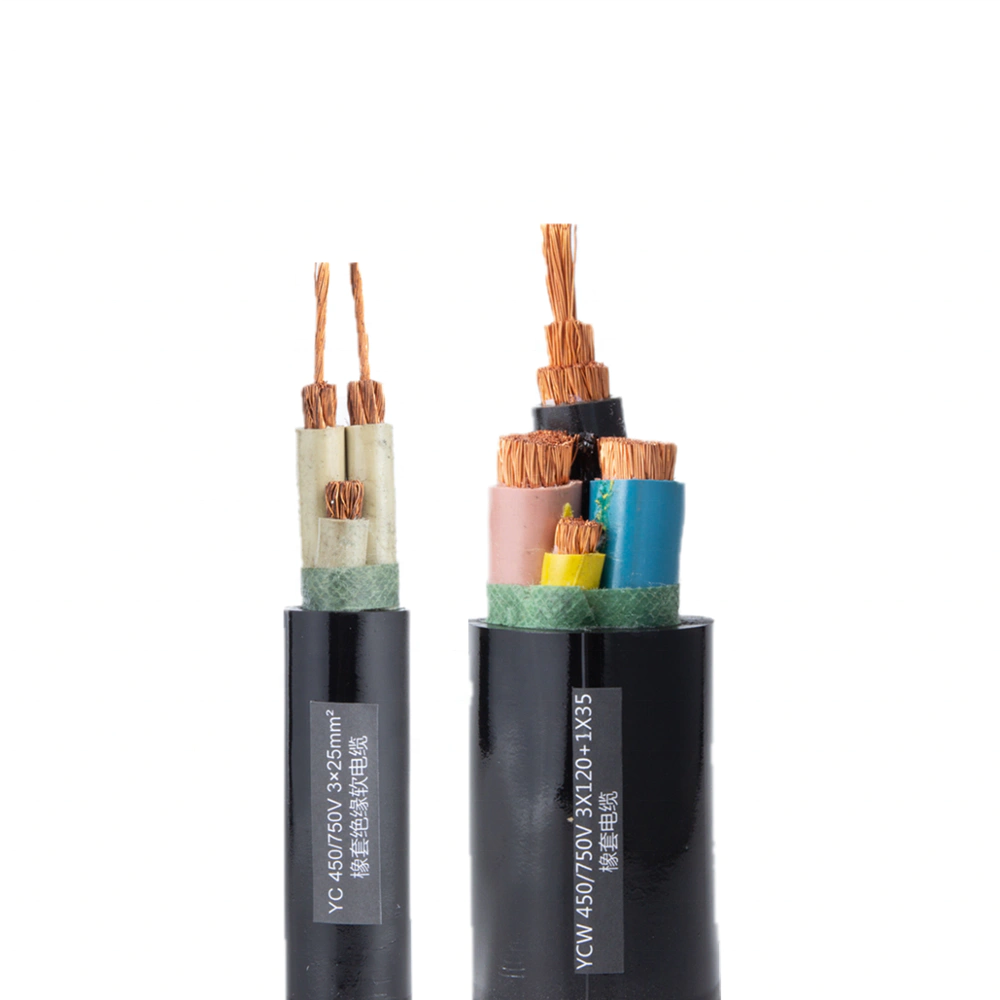

power cable

The products are mainly used in the transmission of strong electric energy in power generation, distribution, transmission, transformation, and power supply lines, with large currents (tens of amperes to several thousand amperes) and high voltages (220V to 500kV and above).

Communication cables and optical fibers

With the rapid development of the communications industry in the past two decades, products have also developed at an astonishing speed. From the simple telephone and telegraph cables in the past, it has developed to thousands of pairs of voice cables, coaxial cables, optical cables, data cables, and even combined communication cables. The structure size of this kind of products is usually small and uniform, and the manufacturing precision is high.

Magnet wire (winding wire)

Mainly used in various motors, instruments, etc.

Flexible fireproof cable

1. Excellent fire resistance. The fire resistance grade not only meets the requirements of international GB12666.6A class 950℃ 90min, but also meets the requirements of British BS6387-1994 A class 650℃ 3h B class 750℃ 3h C class 950℃ 3h and can be resistant to combustion at the same time Subject to water spray and mechanical impact.

2. Long continuous length Whether it is a single-core or multi-core cable, the length can meet the power supply length, and the limit length can reach 2000m.

3. The cross-section of a single-core cable with a large cross-section can reach 1000mm2 and the cross-section of a multi-core cable can reach 240mm2.

4. It is flexible, the cable can be coiled on the cable reel, the bending radius is ≥20D, and D is the outer diameter of the cable.

5. It is smokeless and non-toxic when burned. Inorganic material 'non-combustible' is used for insulation. It will not produce any harmful gas during combustion, let alone secondary pollution. It is an environmentally friendly green product.

6. The cross-sectional capacity is too large, and the cable not only has a large cross-sectional flow, but also has a large overload capacity. According to the wiring requirements, the surface temperature of the cable is usually ≤70℃? If the wiring is not touchable or in contact with combustible building materials, the temperature of the cable sheath can reach 105℃. The allowable working temperature of the fireproof cable can reach 250℃ when overloaded.

7. Corrosion resistance, organic insulated fire-resistant cables sometimes need to wear plastic pipes or iron pipes, plastics are easy to age and become brittle, iron pipes are easy to rust; fire-resistant cables are copper sheathed and do not need to be worn, and the copper sheath has good corrosion resistance.

8. No electromagnetic interference, when fire-proof cables and signal and control wires and cables are laid in the same shaft. Fire-proof cables are shielded by copper sheaths. They will not interfere with the information transmitted by signal and control wires and cables.

9. The safety is good. In addition to the normal power supply in the flame, the fireproof cable can start the fire extinguishing equipment to reduce the fire loss. At the same time, it is also particularly reliable for personal safety. Its copper sheath is a good conductor and the best grounding wire, and it continues to the full length of the cable, which greatly improves the sensitivity and reliability of grounding protection.

10. Long service life, inorganic insulating materials, high temperature resistance, and not easy to aging. Its service life is many times longer than that of organic insulated cables. Under normal working conditions, its service life can be equivalent to that of buildings.

11. The transportation and installation of flexible fireproof cables include installation.

New product

Derivatives/new products of wire and cable are mainly due to different application occasions, different application requirements, convenience of equipment and requirements of equipment cost reduction, etc., and the use of new materials, special materials, or changing product structure, or improving process requirements, or will be different Varieties of products are combined.

Use different materials such as: flame-retardant cables, low-smoke zero-halogen/low-smoke low-halogen cables, termite-proof, mouse-proof cables, oil-resistant/cold-resistant/temperature-resistant cables, etc.

Change the product structure, such as: fire-resistant cables, etc.

Improve process requirements such as: medical cables, etc.

Combination products such as: OPGW, etc.

It is convenient to install and reduce equipment costs, such as prefabricated branch cables.

application

Power Systems

The wire and cable products used in the power system mainly include overhead bare wires, busbars (bus bars), power cables (plastic cables, oil-paper cables (basically replaced by plastic power cables), rubber cables, overhead insulated cables), branch cables (Replace part of the bus), electromagnetic wires, and electrical equipment wires and cables for power equipment.

Information transfer

Wires and cables used in information transmission systems mainly include local telephone cables, television cables, electronic cables, radio frequency cables, optical fiber cables, data cables, electromagnetic wires, power communications or other composite cables.

Instrument system

Except for overhead bare wires, almost all other products have applications in this part, but mainly power cables, magnet wires, data cables, instrumentation cables, etc.

Custom message